Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performance Evaluation of Reclaimed Asphalt Pavement (RAP) Incorporated Concrete for Rigid Pavements

Authors: Muhammad Jalal, Muhammad Sulaiman

DOI Link: https://doi.org/10.22214/ijraset.2023.55689

Certificate: View Certificate

Abstract

The production of Reclaimed Asphalt Pavement (RAP) has seen a recent increase, and Pakistan\'s road network spans almost 100,000 kilometers, with almost 30% of RAP able to be produced from it. This study aimed to explore the use of RAP as an aggregate in rigid pavements. Virgin coarse aggregate (VCA) was partially or completely replaced with RAP at ratios of 0, 25, 50, 75, and 100%. A mix design was carried out to achieve 4000psi, and fresh concrete specimens were cast and tested for slump, temperature, and unit weight. After 28 days of curing, some of the hardened concrete specimens were tested for compression and tensile strength using a Universal Testing Machine (UTM) machine, while flexural tests were conducted on beams. The modulus of adaptability was calculated using UCAM programming with the help of a data logger. The results indicated that compressive, flexural, and splitting tensile strength reduced with an increase in RAP content. However, the modulus of elasticity plots shows that while the stiffness decreased with an increase in RAP content, ductility shows a slight improvement. Based on the findings, replacing up to 25% of VCA with RAP was considered the best permissible replacement in rigid pavement, offering maximum performance. Additionally, a cost analysis of RAP showed a 71% cost saving in VCA and 3% overall section cost saving by replacing just 25% of RAP.

Introduction

I. INTRODUCTION

The Since the first roads were built about 4000 BC made of stone and timber the construction methods of roads have changed a lot [1]. The first roman road was stone paved and were built for military operations in north Africa and Europe. By studying road traffic, stone thickness, road alignment, and slope gradients, road construction techniques were gradually improved, developing stones that were laid out in a regular, compact design, and covered with smaller stones to produce a solid layer. Modern road tends to be built using concrete or/and asphalt. The construction of road can be defined very broadly through three processes i.e. laying out, excavation of earth work, construction of pavement. This is carried out in accordance with the dimensions specified in the model's designs. The profile board approach is a common method for laying out. Along the intended route portion, a series of signs indicating the precise level 1 metre above the level of construction have been positioned at regular intervals. The use of a profile board is a common setting technique. Along the intended part of the road, a series of signs displaying the precise level 1 metre above the finished level are spaced at regular intervals. Each profile board's level is managed by a line level, a short spirit level that is suspended from a nylon thread. Similar operations are carried out at intersections, hammerheads, bays turning, and curves intersecting. Excavation of earth work. Earth work is important process involved in the making of road In this process the top soil is removed, tress, vegetation and other obstruction before the formation level. This is usually done by the grader, tractor and bulldozer. Below the formation level the soil is called subgrade. It is important to check the bearing capacity of subgrade before the start of the work. Most earthwork are made by fill and cut, as well as the type of fill material, the conditions under which it is utilized, the compaction method, and not only the material's physical characteristics. Depending on the condition of the sub soil if it is is weak or loss it should be removed or partially filled if the cost of removing or filling is uneconomical than it should be fill with brick whacks Sub soil drainage should be provided due to the seasonal rise and fall of water table through pavement and edges, on higher ground. From the strength of subgrade we can determined the thickness of the layer the subgrade should strong. The subgrade should be made strong by the following techniques.

- By cutting process we can remove the low strength soil with high strength soil.

- Cement grouting.

- Providing a good drainage system for subgrade.

- Injecting chemical and bituminous material.

- Higher the moisture content decrease the strength of subgrade for the protection of moisture the following measures should be taken.

- Plastic sheet of 30 mm and bituminous binder should be provided.

When the subgrade is formed and path for the water is provided and all the necessary item like gas pipe, electricity wire, telephone wire are covered than paving start. Pavement are of two type i.e. rigid and flexible depending upon the location and nature of the road .in hilly areas we often provide rigid pavement and in plain areas we provide flexible pavement both type of paving have its own advantages and disadvantages .Rigid pavement have high initial cost but low maintenances cost, also rigid pavement have high flexure strength and low tensile strength on the other hand the flexible pavement have low initial cost but maintenances cost is low, high tensile value and low flexure strength

In flexible pavement each layer have its own thickness in order to prevent the deformation, unevenness running surface. The layer should be such that the traffic load is distributed to the subgrade. In flexible pavement there is subgrade, compacted by subbase and then surfacing. In surfacing there is base layer and wear coarse.

The bituminous material is the upper layer of wearing coarse. The thickness depends on the nature of the material and nature of the wear. Low skid, serviceability, comport ride are the desired properties. Hot rolled asphalt, dense bitumen macadam, dense tar macadam and porous asphalt are the principal material. Porous asphalt is very good because of high drainage capabilities and reducing noise of the tire.

The subbase is paced over the subgrade and its size should be 150 mm Different kind of material is use in subbase like stone crush and concrete mix of ratio 1:15.

Flexible pavement is frequently used in nations like Pakistan. . Its primary flaw is that it was made with poor design. Costs for flexible pavement ranged from 300 to 150 rupees per square foot.

The use of reclaimed asphalt has been growing all around. There are 6.5 million kilometer of street structure in the United States that make it the world most street network. Federal highway administration (FHA) estimates that almost &(million tons of Rap are collected from existing asphalt roads each year. It makes it nearly 30 to 40 percent of the total production of asphalt. There was also a stockpile of 93 million tons of Rap, saving 50 million cubic yards of landfill space. Rap is now being used as an aggregate for asphaltic motorways in India. Tragically, relatively few nations employ hard pavement with Rap. On cement roads and occasionally on asphalt, India has utilized it in the past. Rap has only really been employed in a small number of nations. The use of Rap as aggregate in stiff pavement was the aim of this study. Almost all recycled materials end up in landfills because they are never utilized.

The requirement for infrastructure, such as bridges, roads, and buildings, grows as population rises day by day. Road usage is one of these structures that is rapidly growing. In Europe, accessible rap made up 49.6 million tonnes of the 276.4 million tonnes of black top (17.94 percent) Similar to how the estimated 100,000 km of asphalt roads in Pakistan are being dug up to build new streets around the country, moving it elsewhere would present appropriate environmental risks. Usage of Rap in rigid pavement reduces costs while also producing energy. As the BRT was introduced in Peshawar, a sizable portion of the black top roadways were removed to make room for the new track that the BRT would use. In addition, flexible pavements structural life is 30 years and has a higher flexural and compressive strength making it progressively appropriate for use in Pakistan. Pakistan therefore needs to construct rigid pavement using Rap as an aggregate within it. So making of new roads and maintenance of exiting road should be done .by making new roads the resources of natural aggregate decreases day by day so in order to overcome this problem the use of RAP is best alternative to natural aggregate .by using RAP the cost of the road decrease. The waste from demolishing of asphalt is used in sub-base and filing of embankment which is not good use of asphalt so to make suitable use of asphalt, it should be used with natural aggregate and also the waste of Rap that is burden on the environment should be used in proper way. RAP can be obtained by different process i.e. by milling process or by drilling process. The material obtained by drilling process is finer as compared to obtained by drilling. The rap can be used in different proportion with the natural aggregate i.e. 25%, 50%, 75%. It is concluded from different research that by adding rap to natural aggregate the mechanical properties (compressive strength, tensile strength, slitting tensile and modulus of elasticity) changes.

The research novelty of this study is focused on finding the optimal ratio of Recycled Asphalt Pavement (RAP) material and coarse aggregates for use in the construction of strong and durable rigid pavements, as well as identifying potential cost savings through the incorporation of RAP in the construction process. This research aims to contribute new knowledge and insights to the field of road construction, specifically in the area of using recycled materials in the construction of rigid pavements.

The study will address the current gap in understanding of how RAP can be effectively utilized in rigid pavement construction and how it can potentially reduce costs compared to traditional construction methods. This research aims to provide practical and applicable recommendations for the use of RAP in rigid pavement construction, which can be of benefit to construction companies, government agencies, and other stakeholders involved in the planning and construction of roads.

There are several potential limitations to this research study:

a. Time and Resources: Conducting a comprehensive study on the use of RAP in rigid pavement construction may require a significant amount of time and resources, including funding for materials, equipment, and personnel.

b. Data Availability: Accurate and relevant data on the properties and performance of RAP in rigid pavement construction may be limited or difficult to obtain, which could hinder the ability to draw robust conclusions from the study.

c. Real-world Application: The results of this study may only be applicable to the specific materials, conditions, and construction methods used in the study, and may not necessarily be transferable to other contexts or situations.

d. Experimental Variability: There may be inherent variability in the materials and conditions used in the study, which could affect the accuracy and reliability of the results.

e. External Factors: External factors such as weather, traffic, and maintenance practices may also impact the performance and durability of the constructed pavements, and these factors may not be fully controlled or accounted for in the study.

f. Generalizability: The results of the study may not be generalizable to other types of roads or construction methods, and may only be applicable to the specific context of the study.

The scope of this research study is focused on the use of RAP in the construction of rigid pavements. The study will investigate the optimal ratio of RAP and coarse aggregates for use in the construction of strong and durable rigid pavements, and will aim to identify potential cost savings through the incorporation of RAP in the construction process. The research will focus on the technical aspects of using RAP in rigid pavement construction, including its physical and mechanical properties, and will seek to understand its impact on the performance and durability of the constructed pavements. The study will be limited to the use of RAP in rigid pavement construction, and will not consider other types of recycled materials or construction methods. The research will also be limited to the specific context and conditions of the study and the results may not be generalizable to other types of roads or construction methods.

The use of Recycled Asphalt Pavement (RAP) in the construction of roads has received increasing attention in recent years as a means of conserving natural resources and reducing costs. Several studies have been conducted to assess the performance and suitability of RAP for use in road construction, particularly in the construction of flexible and rigid pavements.

Suebsuk et al (2014) conducted an experiment to investigate the effect of RAP on soil compaction and unconfined compressive strength in Thailand. The study found that the compaction and strength of soil decreased as the percentage of RAP increased, with a 3.5% decrease in porosity at a specific point. Shei et al (2017) conducted a study to formulate mix designs and assess RAP support for Portland Cement Concrete (PCC). The study found that the compressive, splitting tensile, and flexural properties of PCC decreased as the percentage of RAP increased, with the greatest decline in compressive strength and the least decline in flexural and splitting tensile strength.

Shie et al (2018) conducted a study using the pavement ME model to evaluate the use of RAP in Continuously Reinforced Concrete Pavement (CRCP). The study found that the load transfer efficiency of RAP-supported CRCP was good. In a separate study, Shie et al (2018) conducted a sustainability evaluation of RAP aggregate in PCC pavement, finding that the life cycle of RAP-supported pavements was comparable to that of plain PCC pavements. Shie et al (2018) also examined the two-parameter fracture attributes of RAP-supported PCC in semicircular bending tests, finding that the tensile strength and fracture energy of RAP-supported PCC decreased with increasing RAP content.

Overall, these studies suggest that the use of RAP in road construction, particularly in the construction of flexible and rigid pavements, can offer benefits in terms of cost savings and environmental sustainability. However, the performance and suitability of RAP may vary depending on the specific materials, conditions, and construction methods used, and further research is needed to fully understand the potential benefits and limitations of using RAP in road construction.

The use of RAP in road construction has been the subject of additional study in addition to the ones already listed. Using RAP in asphalt mixtures was researched by Jang et al. (2015), with an emphasis on how RAP affects the functionality and longevity of asphalt pavements. The study found that the use of RAP resulted in improved rutting resistance and fatigue resistance but had a negative impact on the stiffness and low temperature cracking resistance of the asphalt mixtures. The authors concluded that the use of RAP in asphalt mixtures can be beneficial, but care should be taken to optimize the RAP content and other mix design parameters to achieve the desired performance and durability.

Kumar and Singh (2016) conducted a study on the use of RAP in the construction of flexible pavements. The study found that the use of RAP in flexible pavements can result in significant cost savings compared to traditional construction methods, but may also result in reduced performance in some cases, particularly at higher RAP content levels.

The authors recommended further research to optimize the use of RAP in flexible pavements and to develop guidelines for its incorporation in different types of roads.

Zhang et al (2017) studied the use of RAP in the construction of ultra-thin white topping (UTWT) pavement, which is a type of rigid pavement characterized by a thin layer of concrete over an asphalt base. The study found that the use of RAP in UTWT pavements can result in improved fatigue resistance and reduced cracking, but may also result in reduced early-age strength and increased shrinkage.

The authors concluded that the use of RAP in UTWT pavements can be beneficial, but the optimal RAP content and other mix design parameters should be carefully considered to achieve the desired performance.

Overall, these studies suggest that the use of RAP in road construction can offer benefits in terms of cost savings and environmental sustainability, but may also have some negative impacts on the performance and durability of the constructed pavements. Further research is needed to fully understand the potential benefits and limitations of using RAP in different types of road construction, and to develop guidelines for its optimal use.

Other research has examined the use of RAP in various aspects of road construction, including the use of RAP in asphalt mixtures (Jang et al, 2015), the incorporation of RAP in flexible pavements (Kumar and Singh, 2016), and the use of RAP in ultra-thin whitetopping (UTWT) pavements (Zhang et al, 2017). These studies have generally found that the use of RAP can offer benefits in terms of cost savings and environmental sustainability, but may also have some negative impacts on the performance and durability of the constructed pavements

One area that has received relatively little attention in the literature is the use of RAP in the construction of rigid pavements, particularly in terms of identifying the optimal RAP content and mix design parameters for achieving strong and durable rigid pavements. This represents a significant gap in the current knowledge base, as the construction of rigid pavements is a common practice in many parts of the world, and there is a need to identify cost-effective and sustainable construction methods that can meet the performance and durability requirements of these types of pavements.

The impact of RAP on the long-term functionality and longevity of constructed pavements is another topic that needs more research. There is a need for greater research on the long-term performance and durability of RAP-supported pavements under various types of traffic and environmental circumstances, even though multiple studies have looked at the short-term performance of RAP-supported pavements.

This knowledge is essential to building pavements that are inexpensive, environmentally friendly, and able to accommodate a variety of road types and volume of traffic. There is also a need for more research on the impact of RAP on the sustainability of road construction. While previous research has examined the environmental and economic benefits of utilizing Recycled Asphalt Pavement (RAP) in road construction, there is a dearth of comprehensive studies that consider the full sustainability impacts of RAP-supported pavements.

These impacts include the potential for RAP to decrease greenhouse gas emissions, reduce resource consumption, and minimize waste generation, as well as the potential for RAP to impact other sustainability indicators such as social and economic impacts, resource efficiency, and overall environmental performance.

II. METHODOLOGY

This chapter deals with detail procedure that is followed during the experimental work. The experimental work consists of procurement of materials, mix design for achieving the desire strength, construction of specimens and performing various tests on these specimens.

A. Materials

The required materials comprise of natural coarse and fine aggregate. The coarse and fine aggregate were obtained from local stock in the premises of Peshawar University. The origin of coarse aggregate was Besai and fine aggregate was of Jalbai region. The properties of coarse and fine aggregate will be discussed in the upcoming sections.

The binding material used in preparation of concrete is ordinary Portland cement. The Portland cement locally available was KOHAT cement which is known for its quality throughout Pakistan. The specified 28 days compressive strength is 10,000 Psi. The fineness of cement was calculated through Vicat apparatus as shown in figure-3.11 was 93.1%. The initial setting time was about 45 minutes and final setting time was 120 minutes.

In Pakistan large amount of Rap material is produced because the old road needs to be repair. So the top layer of road is removed and as a result RAP is produced. According to a survey report Pakistan have a 265000 km of road and most of these roads are made of hot mix asphalt. With passage of time, the top layer of road wears which needs to be removed and repaired with a new layer of asphalt. The reclaimed asphalt needs to be utilized in a proper way because it is burden on environment and none of these material is used in flexible or in rigid pavement. So if we use these materials in rigid or flexible road it will preserve the natural resources of natural aggregate. Recently large amount of rap is produced in construction of BRT in Peshawar. The rap material obtained for this experimental study was obtained through milling of the existing asphalt pavement from BRT of “reach-3 karkhano section”. The quantity of RAP obtained was approximately 1 cubic meter.

C. Specific Gravity Test On Rap

Same method and procedure is used to find out the specific gravity of RAP as done for the natural aggregate .first of all the samples is taken in container and washed thoroughly than the sample is placed in clean water container for 24 hour so that it can absorb water completely , after 24 hour its weight and then placed in the oven and then weight. The specific gravity after calculation was 2.45.

D. Natural Aggregate And Rap Combined Gradation

In order to mix RAP with the natural aggregate we must have to find the gradation of both natural aggregate and RAP aggregate and then make a combine graph of both these aggregate in order to show that of these aggregates follow the same pattern in the graph or not

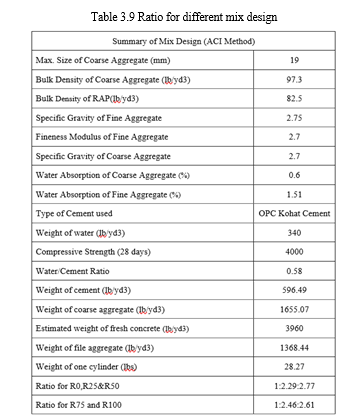

E. Mix Design

Actually mix design show us that which material should be used, and what should be its amount. In mix design we select sand, cement water, aggregate by weight, percentage or by volume. In mix design we first select the strength that what strength we required and then we decide the ratio.

The design of the mix was done using ACI Mix Design method. You will need to pick the following material for mix design.

F. Aggregate

In mix design process first we need to select the aggregate. Aggregate should be of such nature that it should be of regular size, clean, durable hard and strong. Unite weight is used to classify the aggregate. In table 3.10 unit weight of aggregate.

G. Water To Cement Ratio

It shows us the amount water to be added in the mix. 0.57 ratio is for 4000 psi strength

H. Cement Content

From water to cement ratio we find how much of the cement should be used

I. MIX RATIO TRAIL

Different trail are made in order to gain the required strength. The first trail was 1:2.29:2.27 for the strength of 4000 psi. The second trail was 1:2.12:2.47. For 4500 psi. The third trail trail was for 6000 psi and the ratio was 1:185:2.26

J. Adding Rap In Mix Ratio Design

Rap was added in the max at various ratio. First the virgin aggregate is replaced by the RAP aggregate by 25 , 50 , 75 , and 100 percent. After adding the RAP the cylinder for each ratio is prepared. For every single ratio 3 cylinder was formed and then different test is performed on these cylinders. Ratio for different mix design is given below in table 3.11.

K. Water For Ratio

The water used in the mix should be free from all dirt and impurities. Its order, color and its test should be according to the water standard. Therefore engineer are advised to use portable water so achieve the required strength. Different source of water can be use like tap water, river water, municipal water and sea water. 2000ppm is generally acceptable for concrete.

L. Concrete Mixing In Mixer

Mixing of concrete in mixer is an important phase for making samples. The strength of the samples depends upon the mixing of material in the mixer. A small mistake a lead to great loss of strength, therefore its it done in very careful manner. The concrete mixer is first clean so that no old material should be there in the mixer after that the material that cement, sand aggregate and water is weighted on balance and then put into the mixer the mixer is than run for 2-3 minute so that the material is completely mixed.

M. Slump Test

Slump test actually is check whether the concrete is properly mix in the mixer or not. It also show that whether the concrete is workable or not i.e. the ease with which mixing and placing of concrete is done. In slump cone test the concert is poured on clean surface than it is slump cone is filled with the concrete in three layer giving 25 blow to each layer. After this the cone is removed and then the tamping rod is placed horizontally on the top of concrete. The height of concert is measured with help of ruler from bottom to the top of temping rod .the slump may true, shear and collapse slump.

N. Modules Of Elasticity

Elasticity module is a measure of the rate of strain change as a function of stress. As regards tensile testing, it can be called the Tensile Modulus. It shows the slope of the linear part of a stress-strain curve. In modules of elasticity test the cylinder is placed in universal testing machine, the strain gauge is attached to the cylinder with the help of frame. It is also connected to the data logger. In order to find the modules of elasticity UCAM software is used. Maintain as constant as possible the ambient temperature and humidity over the entire test. Carefully align the specimen's axis with the center of thrust of the upper bearing block which is spherically positioned. Once the test starts the system should start recording data. when crack appear on the sample press the stop button.

O. Compressive Test

Great findings were obtained from a compression test on the test specimen. The strength measured 4000 psi after 28 days of cure. . Additionally, the strength reduced as RAP increased. The strength for 25% was not significantly lower it was roughly equivalent to 3000psi at 2900psi. With a rise in RAP, the compressive strength dropped. The following equation was used to calculate compressive strength.

III. RECOMMENDATIONS

- RAP material must include carefully graded particles. This indicates that in order to obtain high slump and strength, every size particle retained up to sieve # 4 must be present.

- In site well graded material shall be used

- In addition to 25% replacement, 15% and 20% should be further researched. If using these ratios reduces the cost of the material by a sufficient amount, it can be tested.

- According to ASTM, the 28th day should be used to test the flexural strength if this is not possible, the 28th day should be used to test the compressive strength. (Don't rely on results from the last week.).

- The micro-structure analysis can also be used to see the internal changes in concrete brought on by the addition of RAP. RAP-PCC.

Conclusion

A. A significant number of aggregates are required for construction, and RAP can assist. B. For a 25% RAP substitution, slump drops by up to 34%, but temperature rises by 4%. C. Compressive strength drops by up to 24.6% for 25% RAP, whereas flexural and splitting tensile strength drop by 13.5 and 24.4% for 25% replacement, respectively. D. Comparing compressive strength to flexural and splitting tensile strengths, the loss in compressive strength is substantially greater. E. Therefore, an increase in RAP has a negative impact on workability, splitting tensile strength, compressive strength, and flexural strength. F. The optimal replacement of RAP determined by the results must not be greater than 25%. G. RAP substitution of 25% results in strength equivalent to M20. mix ratio (1:1.5:3). H. The impact of asphalt ageing can also be observed in the strength. of RAP following VCA replacement.

References

[1] Deshmukh and A. Rabbani, \"Study of Rigid Pavements - Review,\" No. June, 2017. [2] S. A. F. Al-arkawazi, \"Flexible Pavement Evaluation: A Case Study Flexible Pavement Evaluation: A Case Study,\" No. December, 2017. [3] S. Erlingson,\"Road Materials and Pavement Design Rutting development in a flexible pavement structure,\" no. June 2012, 2014. [4] \"Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice,\" no. April, 2011. [5] I. Perspectives and C. Practice, \"Application of Reclaimed Asphalt Pavement and Recycled Asphalt Shingles in Hot-Mix Asphalt, pp. 42-50 October, 2014. [6] J. Suebsuk, \"Strength Assessment of Cement Treated Soil-Reclaimed Asphalt Pavement (Rap) Mixture,\" Int. J. Geomate, Vol. 6, No. 2, pp. 878-884, 2016. [7] X. Shi, A. Mukhopadhyay, and K. W. Liu, \"Mix design formulation and evaluation of portland cement concrete paving mixtures containing reclaimed asphalt pavement,\" Constr. Build. Mater., vol. 152, pp. 756- 768, 2017.

Copyright

Copyright © 2023 Muhammad Jalal, Muhammad Sulaiman. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET55689

Publish Date : 2023-09-10

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online